3D-printed yacht on show at the Miami Boat Show

Windform materials (www.windform.eu) and 3D-Printing technology by CRP Technology (www.crptechnology.eu) will be lowering the anchor at the Miami International Boat Show from February 13th to 17th 2014.

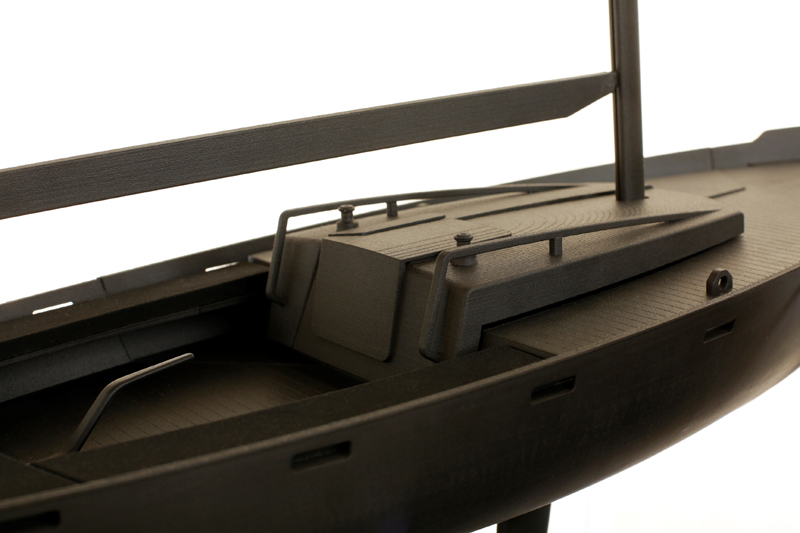

The Italian company ranks among the undisputed leaders in 3D printing and built the prototype of a boat at its Modena headquarters especially for the event, taking the traditional fishing boats found on the island of Pantelleria as its inspiration for the model: the Pantelleria lancia.

The project is the outcome of the partnership between Yam – marine technology and Daniele Cevola Design Studio, and aimed to create a modern version of the fishing boats once built on Pantelleria out of mulberry and maritime pine by the island’s master carpenters.

Today this evolution is called the Livrea26, born in the wind (www.livreayacht.com). YAM and dc*ds set up Livrea Yacht Italia to mark their partnership; it is a project aiming to design various sizes of boats that all share a distinctly family feeling.

As regards the 3D-printed version of the Livrea26, the designers asked CRP Technology to build a 3D-Printed model using Windform materials to go on display at the famous Miami Boat Show held at the Miami Beach Convention Center.

The 1:14 scale model expresses the true essence of 3D printing technology combined with Windform materials, designed and developed by CRP Technology. A design that brings traditional and contemporary elements together, combining futuristic materials and building techniques.

The Livrea26 integrates cutting-edge design solutions and choices that maximise performance and simplify management for simpler boat handling.

By using Windform materials and 3D Printing, it was possible to build the Livrea26 in just a few days while nevertheless safeguarding the utmost accuracy of the most complex details and a strong aesthetic appeal supported by the important mechanical properties of materials usually used in high performance fields, such as motorsport and aerospace.

3D Printing technology used for the first time in boatbuilding by exploiting the superior features of Windform material to build the structural components for a boat, the Livrea26.

The prototype of the Livrea26 is a proclamation of the partnership between CRP Group (www.crp.eu) and the team at Livrea Yacht Italia (www.livreayacht.com), for the development of innovative materials for boatbuilding with the aim of revolutionising the way we design and build watercraft. We could consider the new philosophy behind the project as Boat Building 2.0, since 3D printing and the latest generation materials offer designers the potential to unleash their imagination and experiment with nautical applications.

Video of the boat construction: http://www.crp.eu/2341-windform-3d-printed-yacht-miami-boat-show.html

Press Office CRP Group

Francesca Cuoghi: fcuoghi@crp.eu – +39 059 821135

CRP Group social

Facebook CRP Group

Facebook CRP USA

Twitter @CRP_Group

Google Plus CRP Group

Flickr Crp Group

YouTube CRP Group